Combining our processing know-how with your plant concept

Thanks to decades of experience we can plan and implement entire process chains. In many application areas the process stages are similar or identical to each other. These can include storing, conveying, milling, sieving, fractioning, mixing, dosing, packing, palletizing and loading.

For all these process steps we have suitable machines.

Is your product on the list?

Here are just a few examples of goods manufactured on production lines we have designed:

- baby food

- baking ingredients

- bakery products

- bioethanol

- cassia

- cereals

- spent hops

- malt, flour

- milk powder

- compound feed

- pellets

- pet food

- specialised milling products

- starch

- recyclable goods

Project management from A to Z

In the capacity of general contractors we will assist your project right from the initial planning, delivery, assembly and assembly supervision up until the plant starts operation.

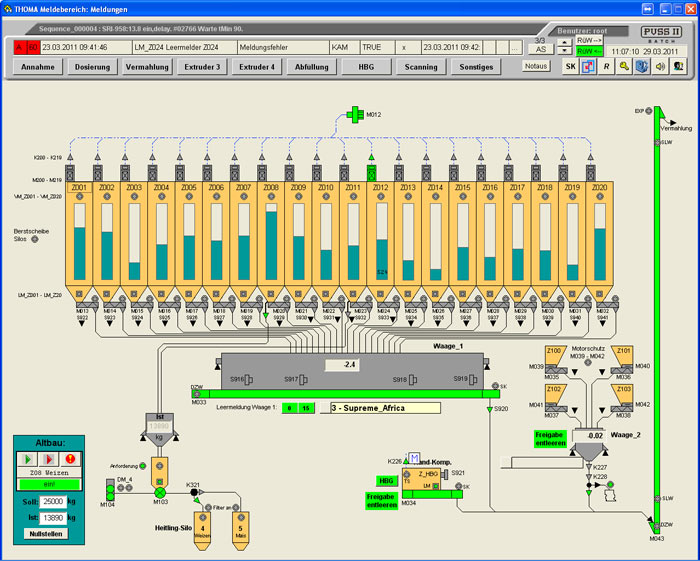

Intelligent control

Whether it be plant visualization, recipe management or programmable automation systems the focus remains the same: establishing controlled and efficient processes.

We integrate into our controlling systems the latest requirements concerning documentation of product flow and traceability.

Complexity requires safety

Highly complex and efficient processes require comprehensive and practicable safety concepts. Therefore our planning and solutions cover:

- Thorough risk analysis

- Consideration of current regulations, standards and requirements, e.g. ATEX, ISO, HACCP, IFS

- Professional installation

- Installation of monitoring devices and suitable filters, bursting discs and burst protection devices.